SOFTWARE

In-Cab Software

CARTel Scale Systems

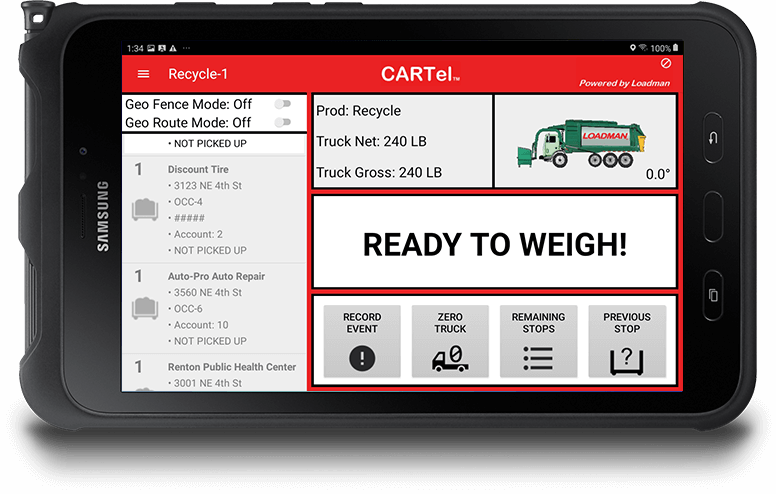

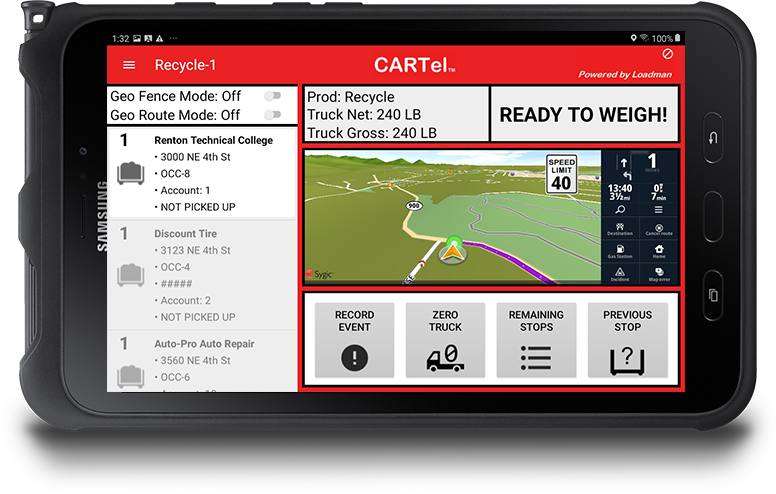

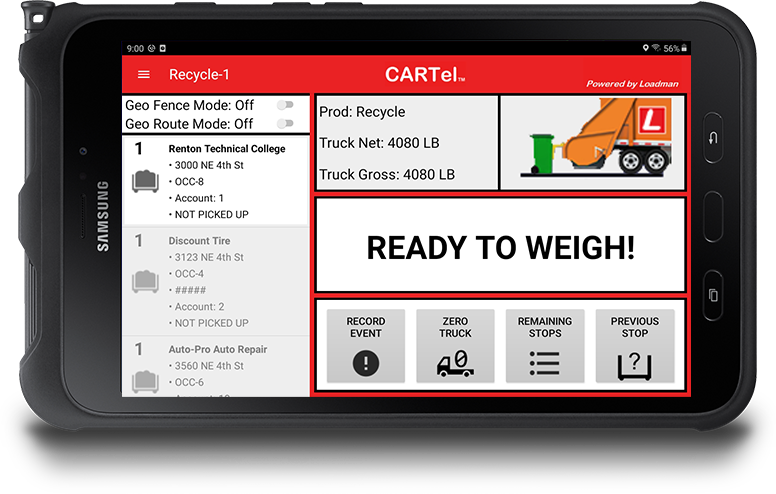

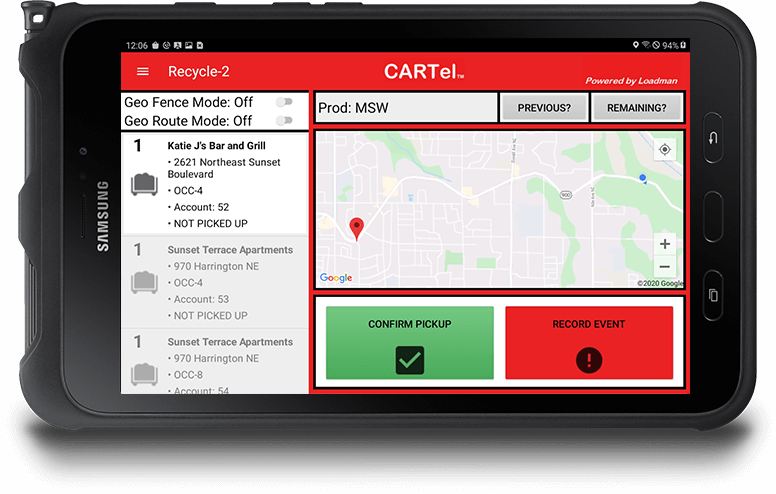

The Loadman CARTel android application is a comprehensive data collection system and driver interface for use with Loadman On-board scales.

The application can send detailed information about individual load pickups including the weight of the load, which customer was serviced, the GPS coordinates of the pickup and what kind of product was loaded.

The Loadman scale system can use several different methods of assigning loads to specific customers. It can be as simple as a sequential list of stops that the driver follows on their route, or it can use more advanced techniques like using GPS data or an RFID system. In each case the application needs little to no input from the driver.

Refuse Front Loader Weigh-In-Motion Systems

Cart Tipper Weigh in Motion Systems

The driver is provided with an interactive interface with information about their route and details about the truck. They can see information about their route such as how many stops are left or what their previous stops were. They can also optionally use a turn by turn navigation system to help with their route. They can view information about the scales such as the net weight of the payload or any error messages indicating a scale malfunction or the truck being overloaded. We also provide a messaging service to display text on the tablet when a message is sent from our cloud software.

The application can also send reports of problems preventing a truck from servicing a customer. The driver can optionally send a data record with information regarding why they can’t perform the pickup along with an optional picture that they can take with their android device.

The application can be password protected and require drivers log in with credentials to access the scale system and send data. This feature can also be turned off if necessary. The application can also access any and all settings of the scale system in case of the need for calibration or troubleshooting. The scale system settings can be under another layer of password protection.

UnderBody CanBus Systems

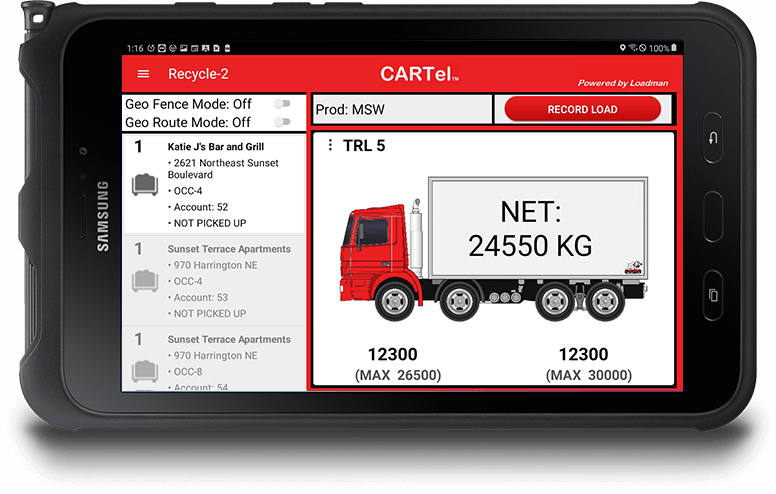

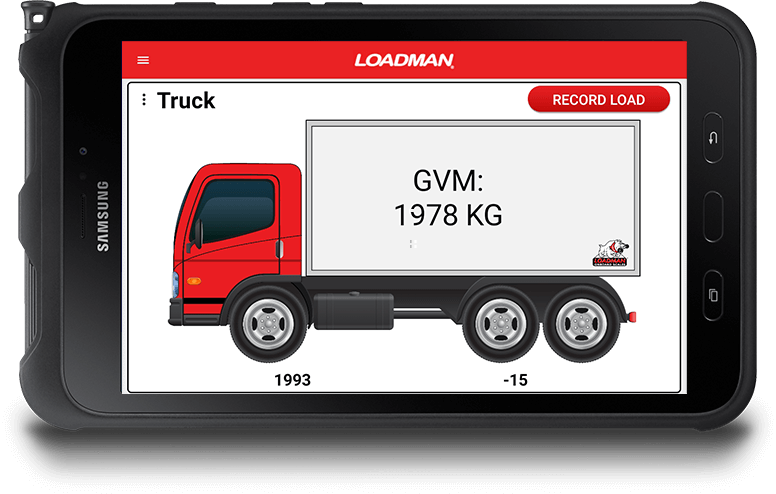

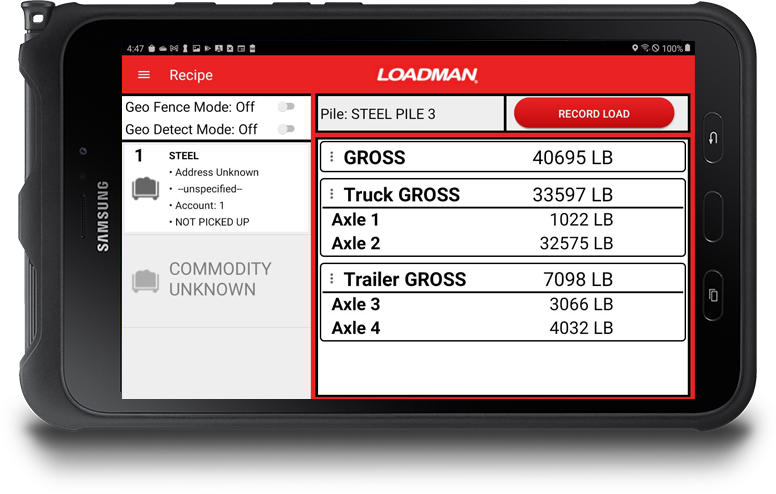

The Loadman UnderBody CanBus Application is intended for multiple trailers (up to 7) with multiple axles and are approved by the Australian Government to support “Truck Trains”. They are data collection and route assistant systems for use with rigid underbody systems.

The underbody system interfaces with Loadman scales on axle groups of a truck and delivers weight data to the Loadman cloud system. The data includes information such as the weight on each axle group, the net and gross weights of any and all trucks and trailers, as well as GPS location data.

Load records can be sent manually with the touch of a button, or alternatively an interval ranging from 10 seconds to a few hours can be enabled to deliver weight data throughout the time the truck is operational.

The driver is provided with an interface to show all current weight readings on the scales, as well as any important messages such as the truck being overloaded or the scales not being connected. The driver also has access to a route with individual pickup sites or customers and whether or not they have been serviced.

The application can be password protected and require drivers log in with credentials to access the scale system and send data. This can also be turned off if necessary. The application can also access any and all settings of the scale system in case of the need for calibration or troubleshooting. The scale system settings can be under another layer of password protection.

LoadCoder™ UnderBody Systems

The LoadCoder™ UnderBody Systems are based around LoadMan’s 2-Wire Patented digital LoadCoder™ technology which provides power and digital signal communication over the same 2 wires to the loadcells on the truck. LoadMan has been successfully providing this patented 2 wire digital technology for several decades now and the Tablet interface provides further support for not only new systems but also older systems currently in the field. This system is normally used for Log Trucks, tipping body Trucks, Dump Trucks with Truck and/or Trailer, rigid frame Trucks, Mining Trucks plus other platform scale Applications. The Application can be loaded on the either larger screen Android Tablets or alternately Android Phone size devices. One added feature is if you order the wireless bluetooth option, the device can wirelessly communicate at distances up to 500 Ft from the Truck’s Onboard Scale. This allows a remote loader or for that matter self-loading Log Truck to load a truck and have full access to the weight information on the Truck and Trailer and/or even Axle Weights of the Truck and Trailer while the truck is being loaded.

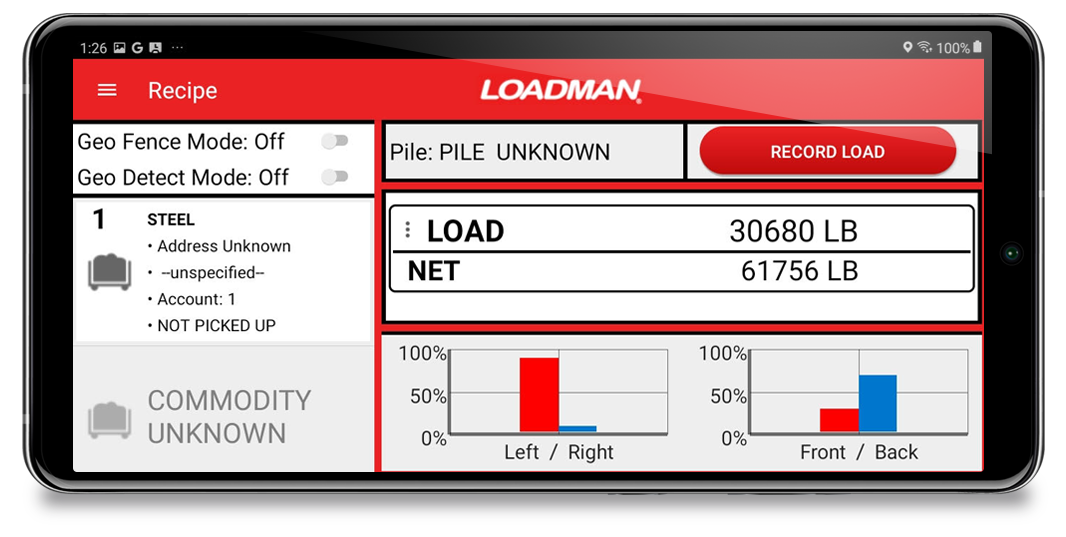

LoadMan Remote Systems

The LoadMan Remote Application allows a remote loader within 500 Ft of the Truck to bring the display that is inside the Truck to an operator in a Remote Loader. This is a handy thing for loader operators especially when it shows how the center of gravity of the load is being carried with graphs which show the Left to Right Loading and the Front to Back loading. For high accuracy systems it is desirable to evenly spread the load which achieves greater repeatability. Also to be able to select a commodity or customer being loaded and the possible pile that it is coming from for operators who desire to get their data collected in a local or cloud database.

Steel Mill Systems

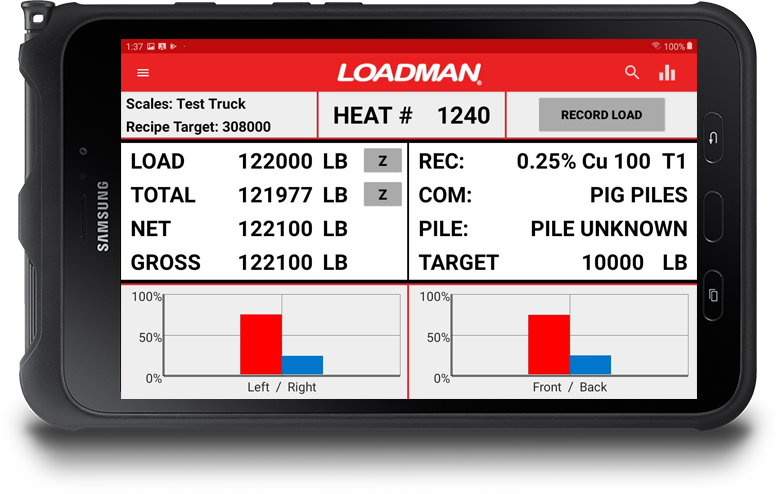

The Loadman steel mill applications are data collection tools and heat management systems for use with Loadman On-board scales.

The operator of the truck or loading crane manually presses a button to record a load for a given recipe step. The application then automatically advances to the next step in the recipe. The operator is shown which commodity to pick up, which pile to get it from and the target weight for each recipe step.

The application interface always shows the current load weight as well as the net and gross weights of the truck and the distribution of weight in the bed of whatever they are loading the commodities into.

Non-Scale Systems

The application without scales allows for drivers to still send detailed information about their load pickups and monitor which customers have or have not been serviced. A route is provided to the driver with a list of customers that can be identified either by following a sequential route, location data or our RFID system.

The driver can manually press a “confirm pickup” button to send a data record to our cloud software indicating they have serviced a customer. The driver can also record information about problems that occur that prevent servicing a customer, including text for what happened and an optional picture that they can take with their android device. For this method, the only thing needed in the entire system is the android device alone, which can be a tablet or smartphone.

With this application, the driver is always provided a map with pins indicating where they are and where their next stop is. Optionally, the application can integrate a turn by turn navigation system.

The application can be password protected and require drivers log in with credentials to access the main operating mode and send data. This can also be turned off if necessary.